Great Plains Facility

Our Great Plains facility was built for the purpose of groundwater protection and has been used to safely store hydrocarbons for years. Vaulted took over the site in 2023 and transitioned it to organic waste disposal with carbon removal.

Start date: 2023

Job Growth: Employs 25+ (and hiring!)

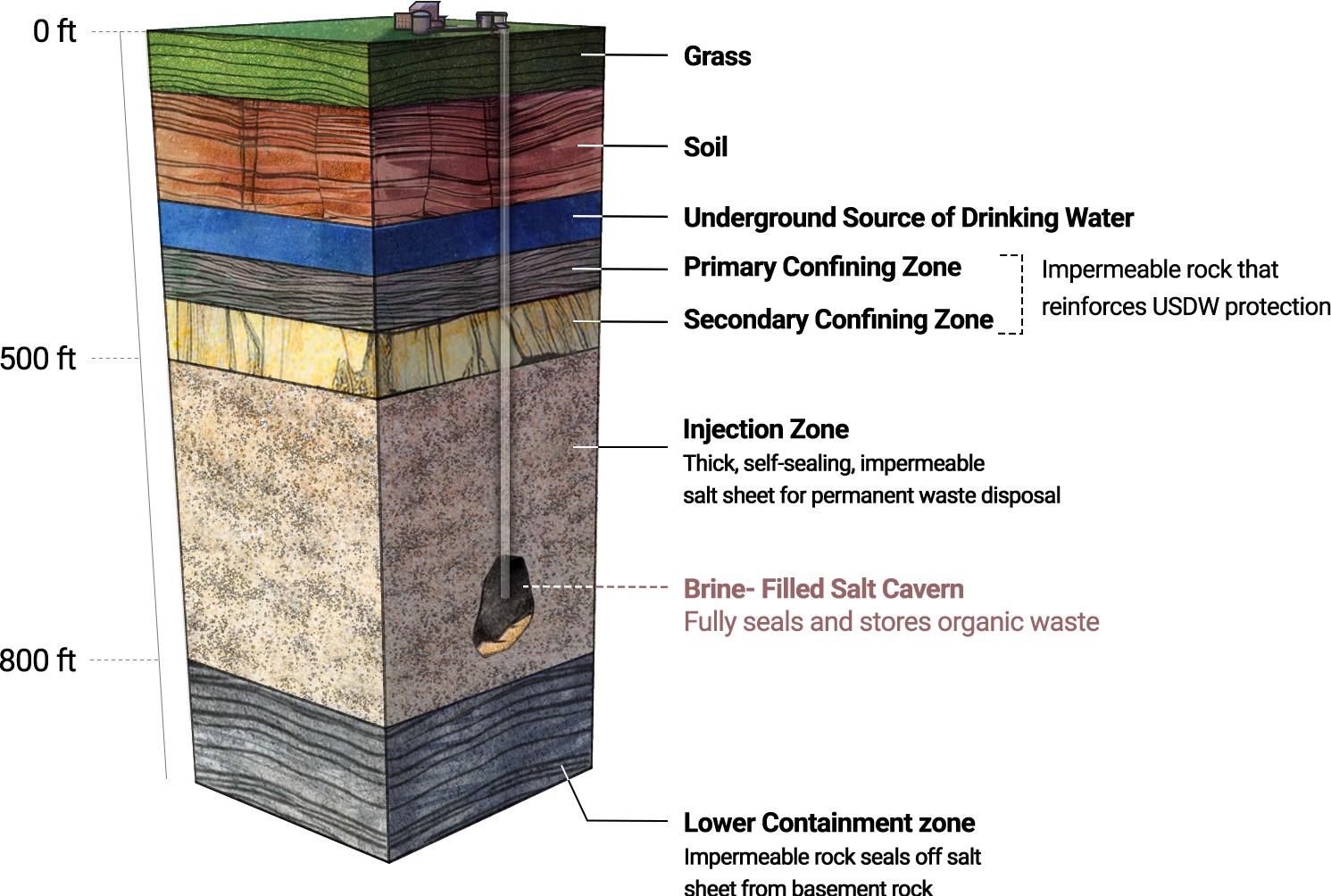

Secure by design

Salt caverns have amazing natural storage properties that we can tap into. At Vaulted’s Great Plains facility, we combine salt caverns’ natural impermeability and self-healing properties with our robust well design, 24/7 real-time monitoring, and rigorous operations to securely contain all waste.

History of safe storage

This facility was originally built in the 1980s to store hydrocarbon liquids — like propane and butane — and maintain clean groundwater. It was re-permitted for safe beneficial reuse of waste materials by Kansas Department of Health and Environment in 2012.

The site has maintained a strong safety record and has had no groundwater contamination incidents in its 15+ year history. We follow rigorous monitoring and operational standards to ensure safe, long-term performance.

Investing in the local economy

$1.8M to local vendors

like trucking companies, rentals, and office supplies

$1.6M in wages

and employee benefits

18+ new full-time jobs

created (and currently upgrading facility equipment so it can take even more waste and employ even more people)